PORTLAND, Ore. — It’s easy to feel like we have no control over what’s happening in our world right now. It’s easy to feel helpless, like this pandemic is too big to grasp or tackle.

But just as easily we can remind ourselves – and one another – that we all have individual skills, passions, talents and hobbies that can make a difference during this pandemic.

That’s exactly what motivated Matias Brecher to step in and try to fill a void.

The deteriorating supply of personal protective equipment (PPE) for medical professionals on the front line of the COVID-19 fight is one of the biggest issues facing our nation.

Brecher is the founder of Toast, a small Portland-based company that creates wood and leather goods for tech devices. Due to the COVID-19 outbreak, Toast's business is cut in half compared to last month.

At the same time, Brecher was shocked to discover what is going on in hospitals, where healthcare workers feel unsafe because they lack adequate protective gear and are forced to reuse equipment.

Brecher felt he had to do something. He decided to design and create plastic personal protective face shields.

“I'm seeing where our economy is going, how businesses are all shuttering and realizing maybe there’s a space for us to help out,” Brecher said. “I'm really feeling a need to help, you know. [I’m not] involved in a medical profession, I’m not directly involved with anybody working the front lines. [But] I don’t feel comfortable just sitting at home twiddling my thumbs.

"Also we’re a small manufacturer, so keeping my employees employed is an important part.”

Toast creating reusable plastic face shields for frontline workers

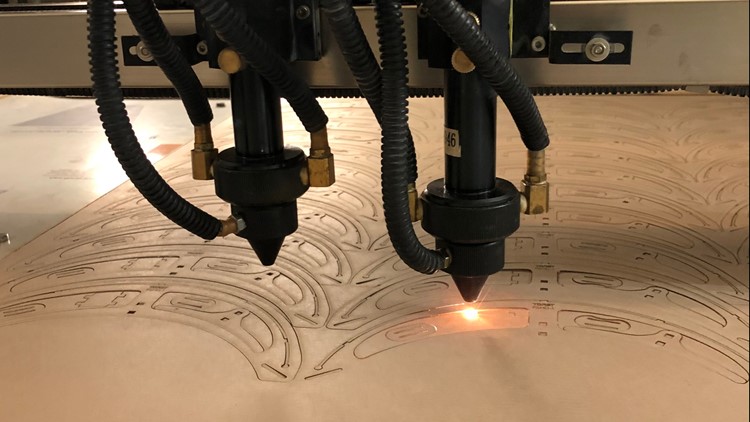

Toast uses large laser machines to laser cut wood and leather products. They are now also using those machines to cut plastic and manufacture face masks, using the skills they have and sourcing the right materials.

Because so much protective gear is one-time use only and disposable, Brecher’s main goal was to create a reusable shield that could perhaps be a better solution to the PPE shortage. He simplified and is using material that can withstand chemical cleaning products like alcohol.

“We’re in a time crunch," Brecher said. "We’re just trying to be a stop-gap. Right now we have people out there who don’t have equipment and they need to be safe. We need them to be safe so they can take care of us.”

Creating face shields is less complex than manufacturing safe and effective N95 masks, and Brecher is confident the shields he’s creating will do the job.

“This is a piece of plastic. Anything you can put in front of somebody so that their face mask is not getting covered with droplets and the virus, protecting their eyes, protecting their nose, allows other equipment to last a lot longer. There’s not a lot of issues with does it work or not work,” Brecher said.

Toast employees began production Friday and have created about 50 face shields so far. Production is starting to ramp up; Brecher says they have the capability to churn out 250 shields a day beginning Monday. If he secures more material, he says they could produce about 500 a day. This is a short-term but much needed solution until large-scale manufacturers get online and plug the holes.

Already, Toast is getting interest locally and nationally and Brecher feels they could fill a niche in helping out smaller hospitals and providers, who are struggling to compete with giant hospital systems to secure PPE.

The face shields are sold online, and purchasing is currently only open to healthcare, hospital and government agencies.

Brecher says they are only breaking even doing this. They charge the cost of expenses, materials and labor to make the shields.

“I think a lot of us there are little pieces we can do,” Brecher told KGW. “Everybody’s got hobbies, they’ve got ingenuity, they’ve got ways they can contribute. It can be simple: by calling the neighbor who is old and doesn’t have an opportunity to get to the store or doesn’t know the ways to order online to get groceries delivered, things like that. We can all help each other out. So I encourage people to do that. Think about the skills that you have.”