GRANTS PASS, Ore. — A grassroots effort, bubbling right here in Oregon, is helping solve one of the biggest problems our frontline heroes are facing: a rapidly dwindling stock of personal protective equipment (PPE).

Healthcare workers and makers joined up to help fill the need.

Brad Converse, an engineer by trade, coordinates and organizes the logistics out of his golf shop in downtown Grants Pass.

He put together a team called "Covid Skunkworks" last Sunday after talking to a Southern Oregon hospital supply chain director.

“Within less than 24 hours we had 35 local experts on the phone where we heard directly from the hospital what is the problem, what do you guys need, and then starting the very next day we were already delivering face shields. By now we have over 150 experts worldwide coordinating on this effort and we've already delivered face shield instructions to the world,” Converse said.

Covid Skunkworks is working to empower people to innovate in their own communities and build the necessary equipment and devices that health care systems need.

Converse and the team of experts provide instructions on their website for how to organize a team made up of health care workers, innovators and makers and delivery coordinators in your community, create 3D prints, assemble parts, sanitize equipment, deliver to the front lines, implement safely and reuse.

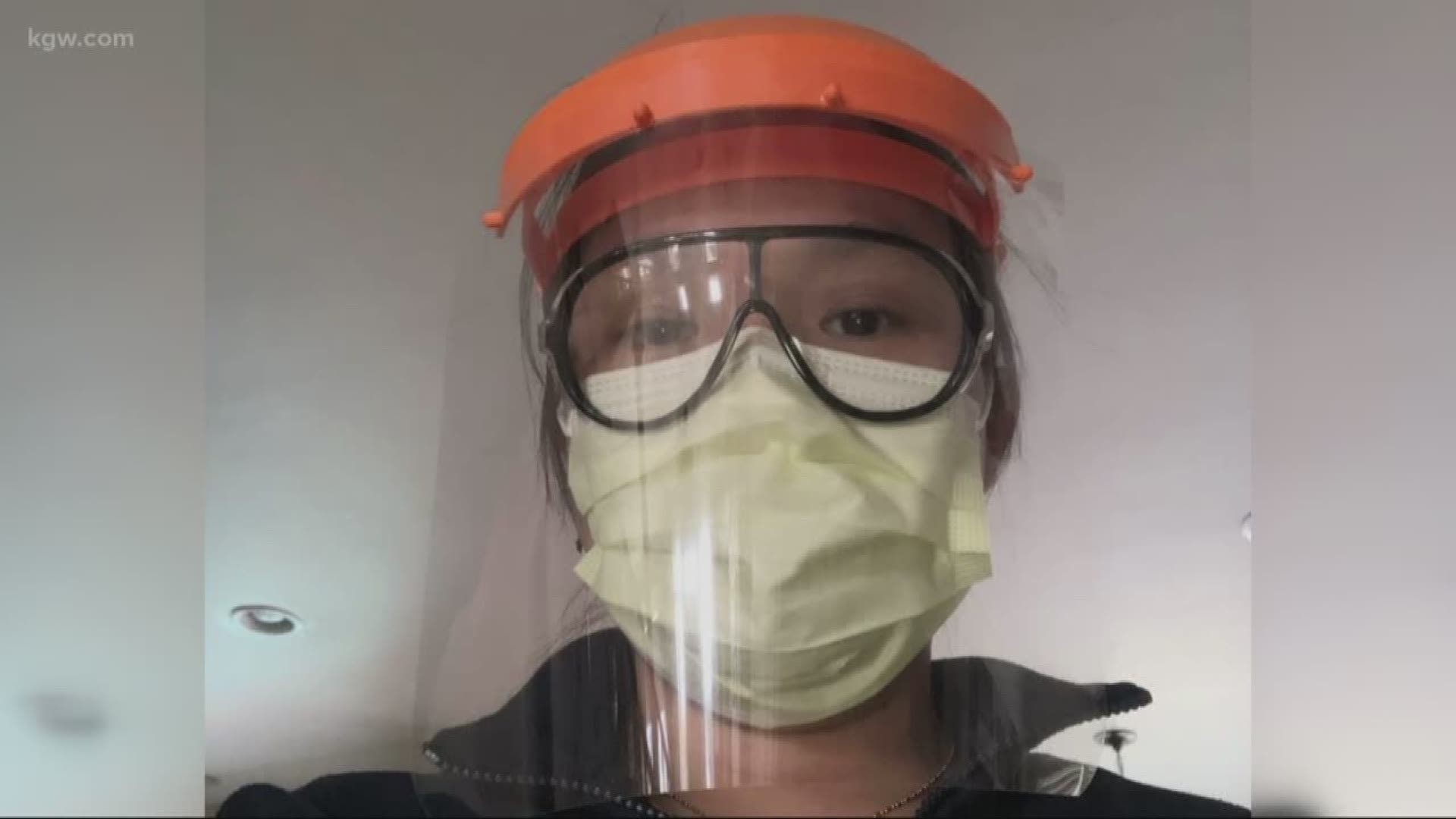

Face shields to shelter health care workers from airborne droplets that could contain coronavirus are just the first piece.

“We weren't going to be getting those for quite a while - if at all - waiting on the government or waiting on big business to step in but now our garages and schools are doing it and we are protecting our own health care,” Converse said. “The instructions we provided will allow for millions of face shields and other parts to be printed right at the source as much as possible."

Directions for designing physician-approved N95 respirators, ventilator parts, filters, and surgical gowns are next. Converse says all designs and instructions for devices and medical equipment are vetted by engineers, physicists and physicians.

“There are some regulatory hurdles just with doctors making sure they can keep their job but they are working directly with senators to get approval to be able to say that they're on board with this. We're tackling this from every angle possible.”

Together with those experts, he created a logistical package, tied up in a bow, with instructions 3D printer users and others can follow.

RELATED: 'I've never felt more vulnerable': Nurse describes fears plaguing workers at Oregon hospital

“Rather than just saying ‘we don't know who you are’ and ‘why are you doing this’ [hospitals] can go to CovidSkunkworks.com to see documentation for why it works, makers can go on there to know exactly how to make it and assemble it, the sanitization team knows exactly how to sanitize it prior to use, the reuse team knows how to sanitize it between uses and how many uses it’s good for,” Converse told KGW.

A patchwork of selfless people, now working together to try to control some of the chaos and help our frontline heroes.

“It's sobering but at least you can hear some hope in their voice and they know we're doing everything we can, at least, to make sure they are protected as they do the frontline work,” Converse said.

The U.S. Food & Drug Administration (FDA) says printed PPE provides a physical barrier but it may not have the same level of fluid barrier protection or air filtration as FDA-cleared gear. The administration has an FAQ page dedicated to 3D printing of medical devices, accessories, components and parts during the COVID-19 pandemic.

The FDA outlines what health care providers should do if they’re using a 3D-printed mask:

- Check the 3D-printed mask's seal for leaks.

- Confirm that they can breathe through any makeshift filter materials.

- Exercise caution in surgical environments where the need for liquid barrier protection and flammability is a concern.

- Recognize that the mask may not provide air filtration enough to prevent transmission of infectious agents.

- Safely dispose of infectious materials and disinfect any part they intend to reuse.

Converse would argue the designs they’re sharing are up to par.

RELATED: 'Nurses wore swim goggles': Oregon nurses union says protective gear could run out by Tuesday